Lubricating oil station (power generation)

Classification:Oil station

Product Details

Pump equipment is a device used to transport liquid or gas, widely used in industry, agriculture, construction and other fields. They generate suction and pressure by rotating components such as impellers to push the liquid flow. Pump equipment has a variety of types, such as centrifugal pumps, reciprocating pumps and rotary pumps, etc., each with its own characteristics, according to different transport needs and scenarios to choose the right type. They play a key role in liquid circulation, water supply, drainage, etc., and are indispensable equipment in many industrial processes.

Keywords:Lubricating oil station (power generation)

Related Products

Pump

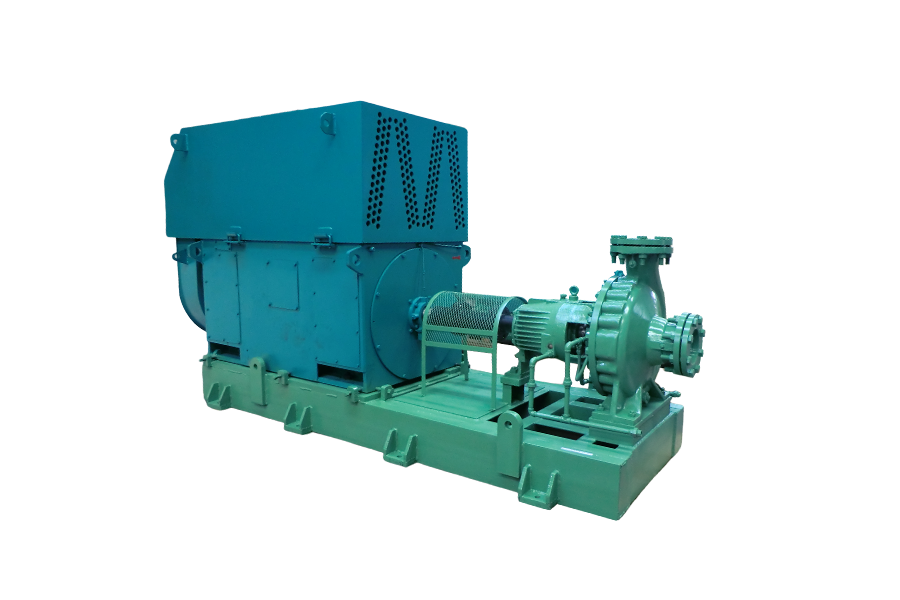

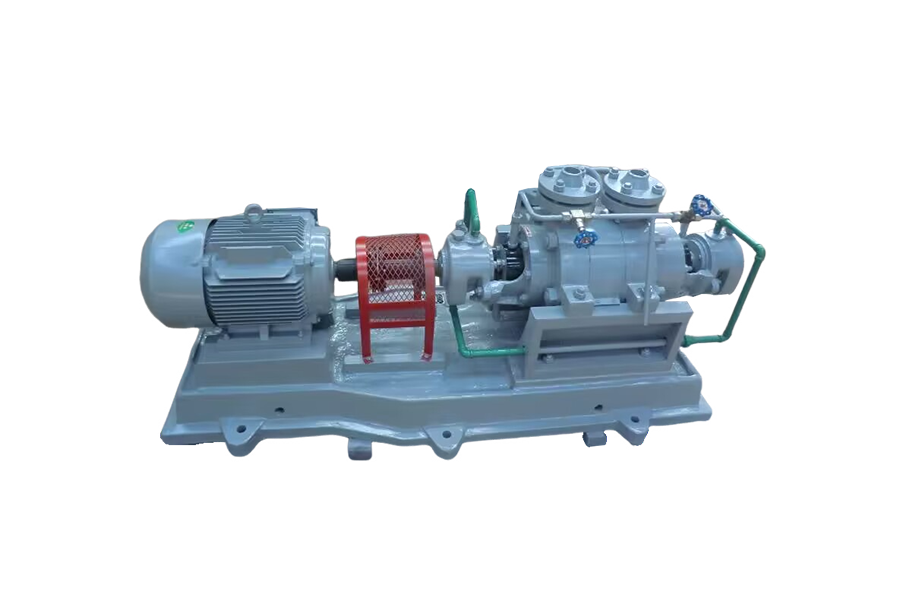

Centrifugal pump

-

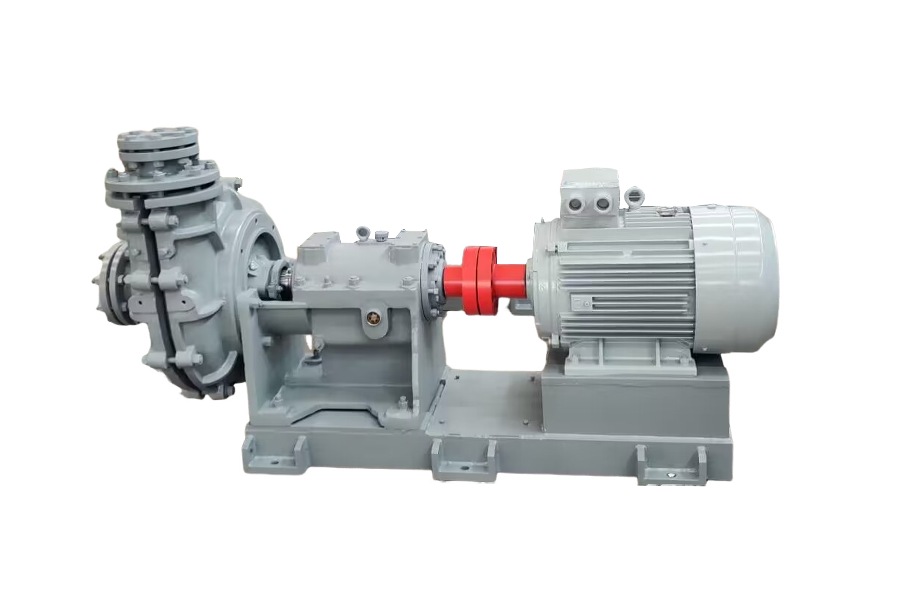

Slurry pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Slurry pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Slurry pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

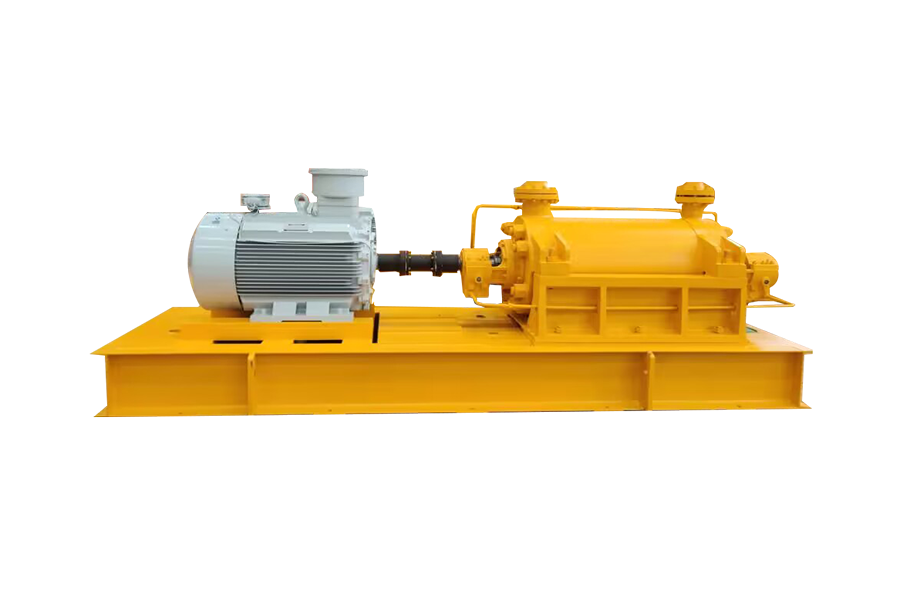

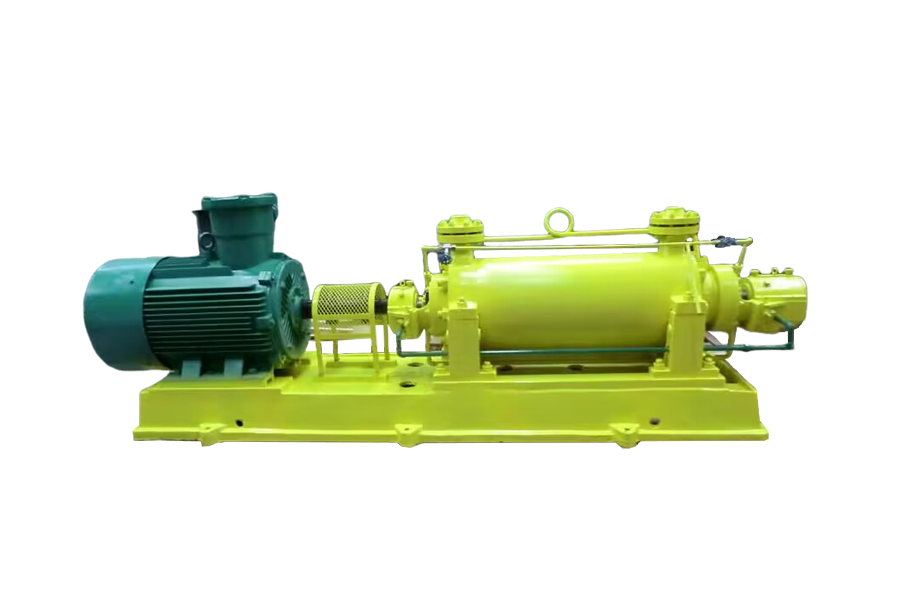

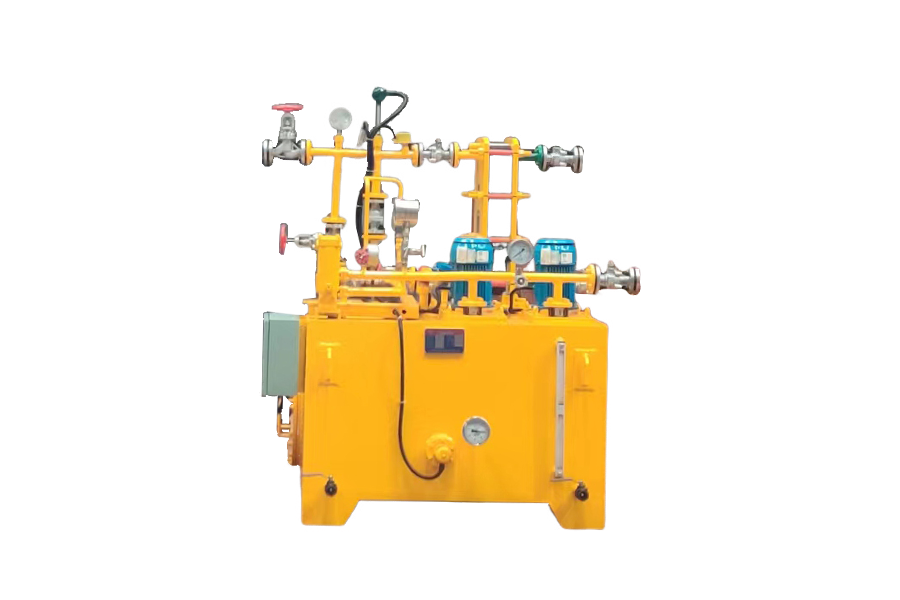

Boiler ignition oil pump

-

Boiler ignition oil pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Boiler ignition oil pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Boiler ignition oil pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Single-stage centrifugal oil pump

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

Oil station

-

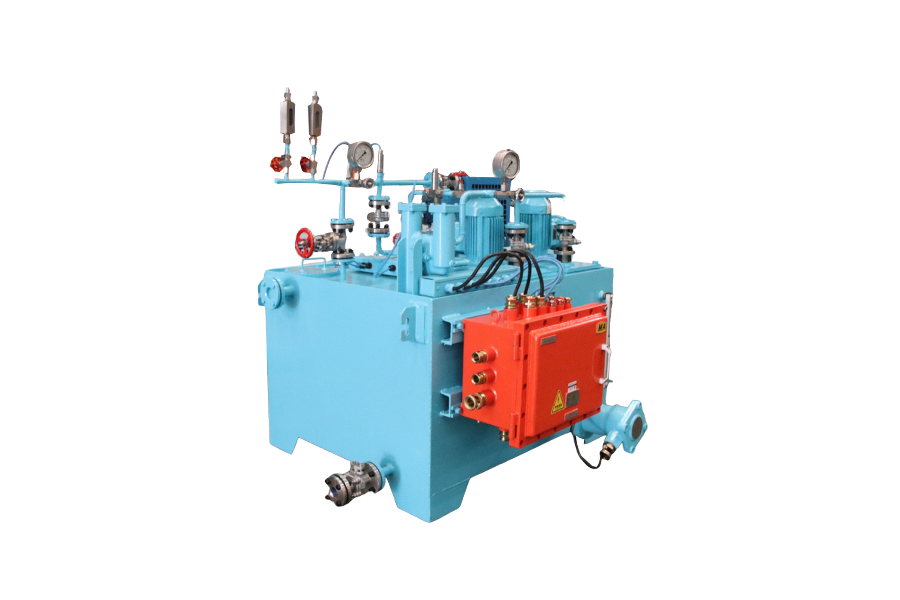

Oil station

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Dilute oil station B

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Lubricating Oil Station A (Chemical)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Lubricating Oil Station B (Power Generation)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Lubricating Oil Station C (Power Generation)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

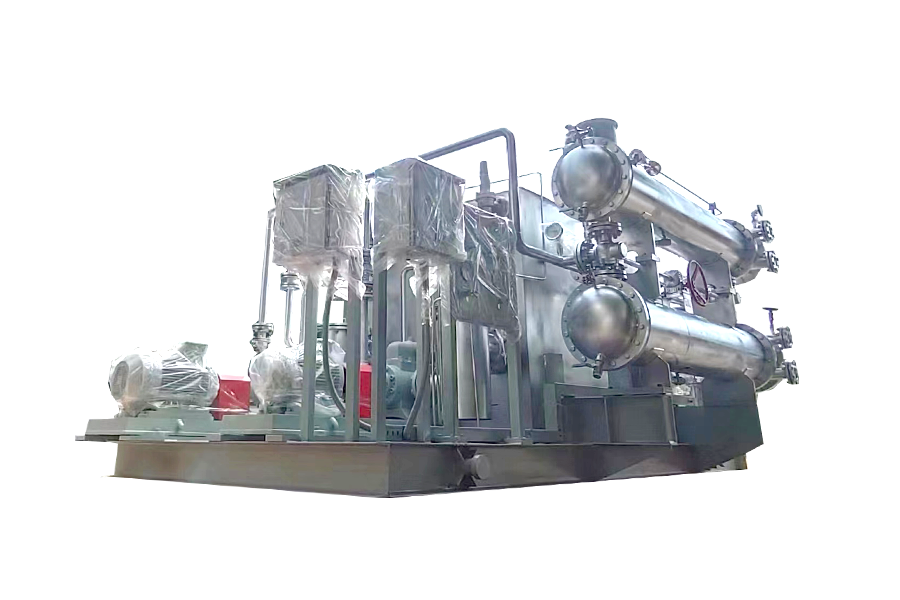

Lubricating Oil Station A (Power Generation)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Lubricating oil station (chemical)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

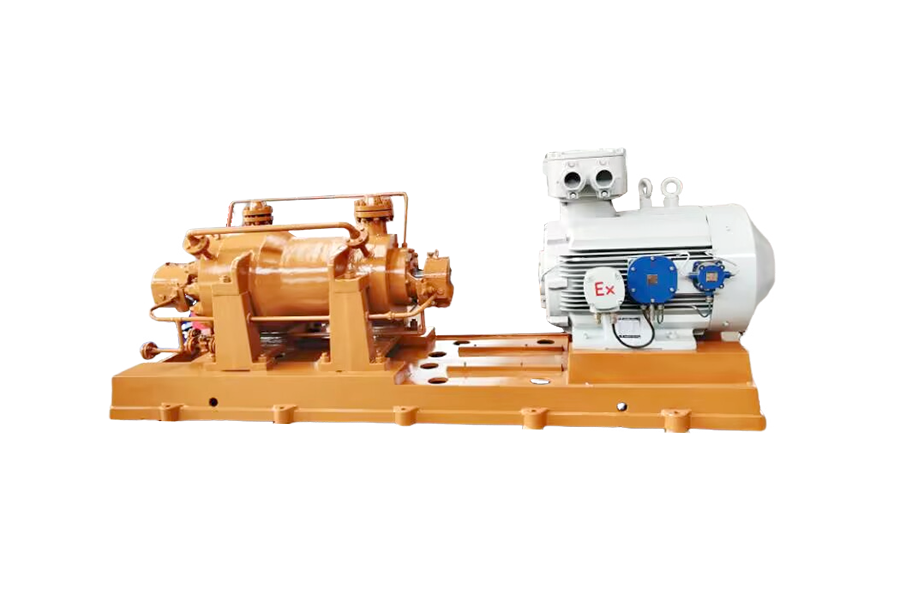

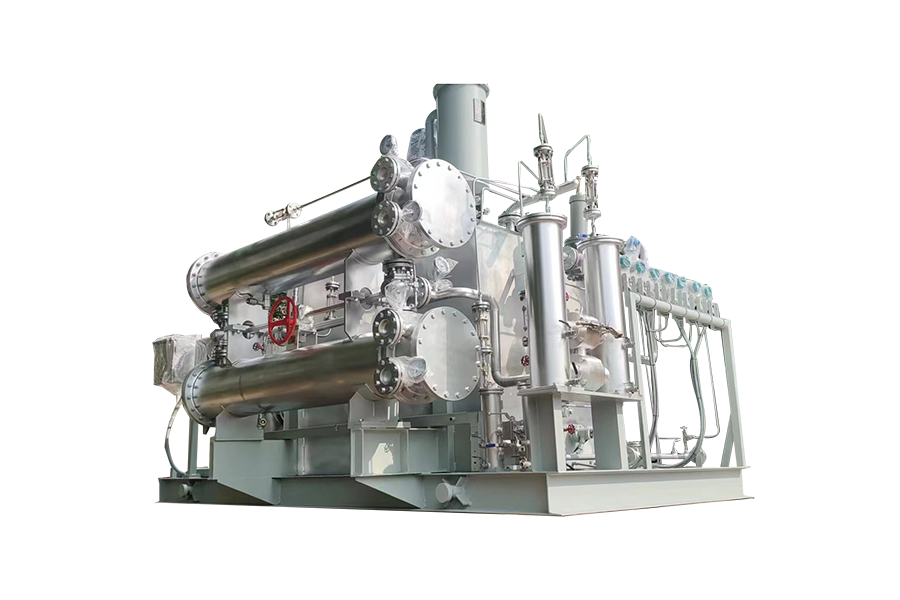

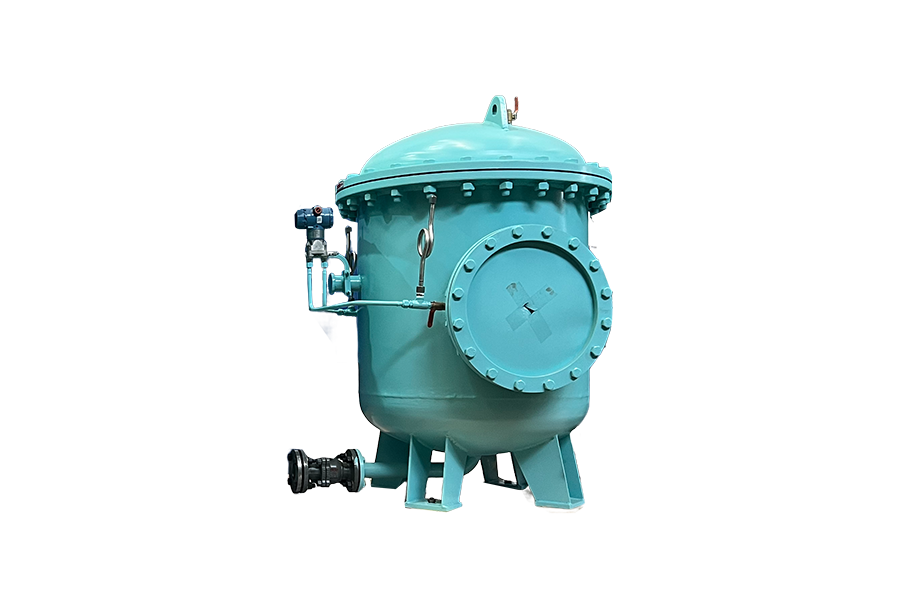

Lubricating oil station (power generation)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

High and low pressure oil station

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

Evolution Filtration Equipment

Oil purification

-

Oil Filter A

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Oil filter B

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Oil Filter C

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

Oil-water separator

Oil filter

Water filter

-

Water Filter C(ASME)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Water filter B(GB)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

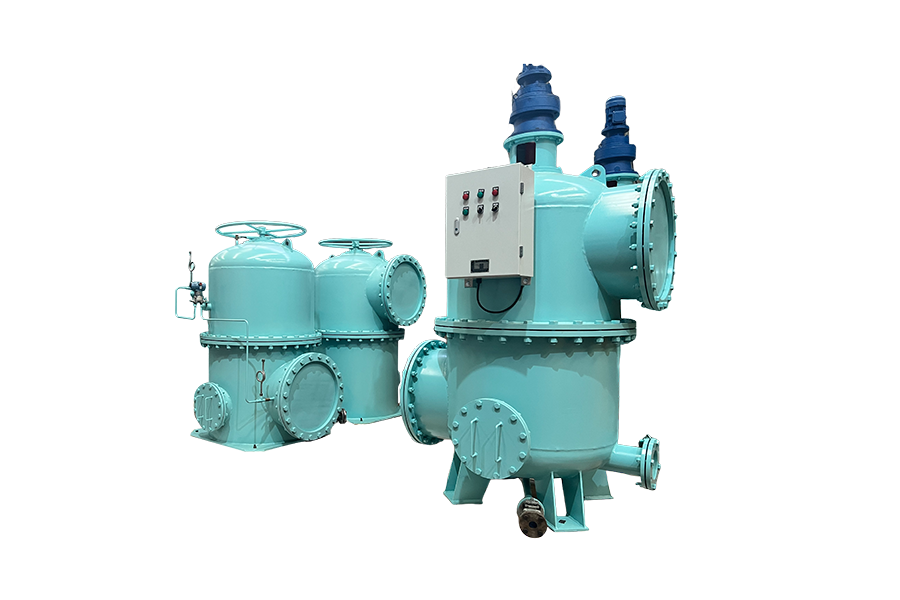

Water filter A(GB)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Water filter A(ASME)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Water filter (GB)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

Pressure vessel (tank)

Skid-mounted equipment (customized)

-

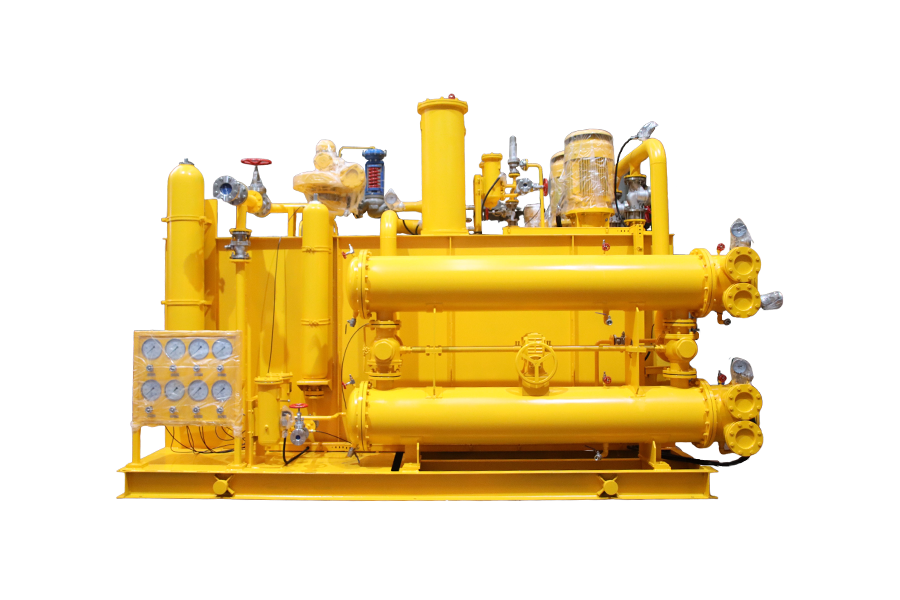

Desulfurization unit (non-standard)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Desulfurization unit (non-standard)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

Desulfurization unit (non-standard)

They generate suction and pressure by rotating components such as impellers to push the liquid flow.

-

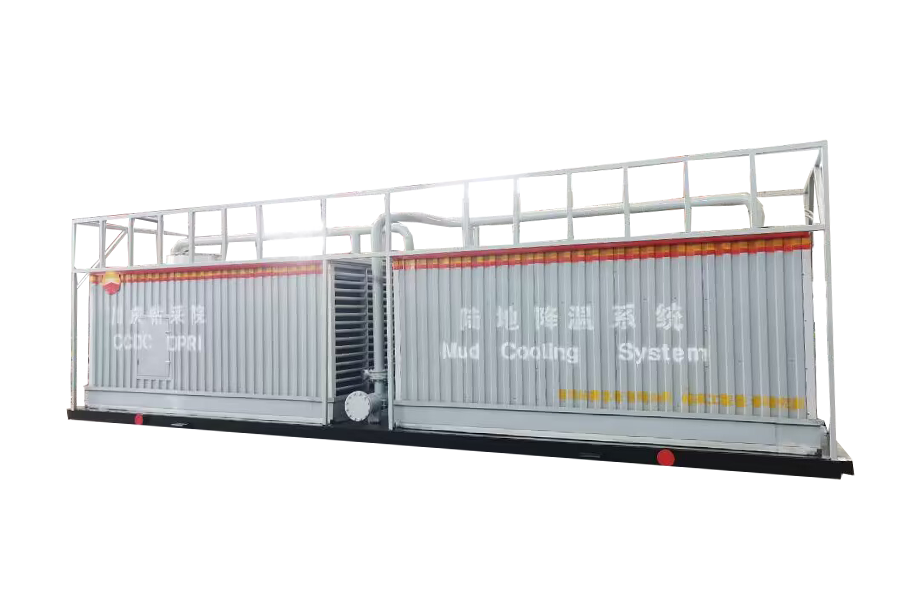

Air preconditioner

They generate suction and pressure by rotating components such as impellers to push the liquid flow.